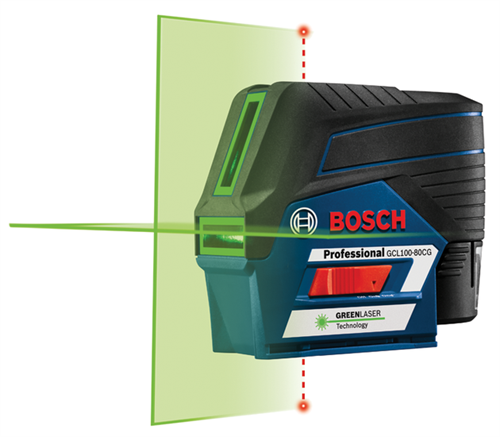

MSRP: $390.00

$129.00

Save: $261.00 (67 %)

|

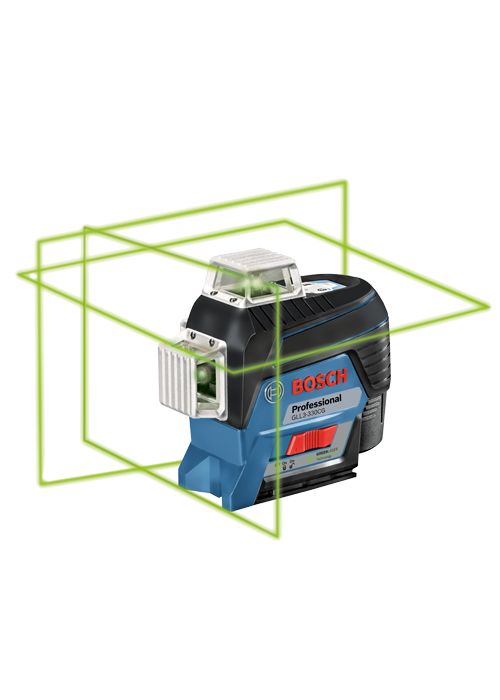

MSRP: $499.00

$379.00

Save: $120.00 (24 %)

|

MSRP: $799.00

$389.00

Save: $410.00 (51 %)

|

MSRP: $799.00

$579.00

Save: $220.00 (28 %)

|

MSRP: $1,299.00

$899.00

Save: $400.00 (31 %)

|

MSRP: $1,499.00

$999.00

Save: $500.00 (33 %)

|

|

|